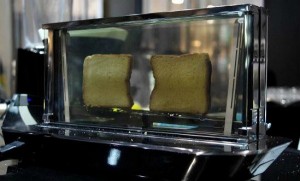

Tesla S Gets A Glass Roof

The panoramic sunroof, which is currently still available, can be had for about $1,500 if you buy, $32 extra per month if you lease. The panoramic sunroof with the center cross member is required if you also want the roof rack and satellite radio.

If you’re worried that a glass roof will treat you like an ant under a magnifying glass on a sunny day, don’t. The glass roof (panoramic or otherwise), blocks about 98% of UV light and more than 80% of the heat that might otherwise be generated. In short, you won’t get roasted!

According to the car’s website, there is no sunshade available for the glass-roofed car (yet), but the car does have a built in “overheat” protection. Owners can also turn on the air conditioning in the car via a smartphone app before returning to the vehicle.

Earlier this year, Tesla announced the Model 3, which incorporates virtually uninterrupted glass from the windshield to the rear deck. While the Model 3 doesn’t use a single piece of glass, it does make heavy use of glass throughout the passenger cabin. The Model 3 isn’t even in production yet, and is unlikely to be consumer-ready before the end of 2017, but other manufacturers are taking note of consumer preferences for glass.

If you don’t think a car in the $75,000 – $100,000 range will work well for your wallet, Audi, BMW, Chrysler, Hyundai, Kia, Lincoln, Mini Cooper, Toyota and Volkswagen all have panoramic sunroof or moonroof options on some of their vehicles.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store

Photo Credit: Steve Jurvetson, via Flickr.com