Embattled Portland Glass Furnace Moves To Mexico

Uroboros, one of the Portland glass furnaces at the center of a controversy regarding toxic heavy metal emissions, has been sold to a California company that intends to move the company to Mexico. Owner Eric Lovell had previously said that the company would close in early 2017, because it was unable to cope with new exhaust filtration requirements.

The new regulations were put into place after officials from the State of Oregon and the US Environmental Protection Agency discovered high levels of toxic metals around the plant. Bullseye Glass, another Portland glass furnace, has installed a massive new filtration system designed to capture toxic heavy metals before they escape the company’s plant.

Bullseye and Uroboros are two major suppliers of colored art glass in the United States. Since the discovery of the plants’ emissions, the US EPA has been conducting tests at other furnaces around the country to determine whether they should comply with EPA emissions regulations. Prior to the discovery of high levels of toxic emissions, the furnaces were exempt from meeting EPA regulations because they were not believed to be in continuous operation.

The furnaces voluntarily reduced production of certain colors of glass to reduce their toxic emissions to acceptable levels prior to installing pollution control systems.

Uroboros was purchased by Oceanside Glasstile, which will move all of Uroboros’ operations to a facility in Tiajuana. According to Lovell, the Portland facility will begin a staged shutdown on February 1. Bullseye Glass will continue to operate, having recently completed the installation of a bag filtration system that will reduce the plant’s toxic emissions to nearly zero. Bullseye increased its production levels late this year, but is now addressing concerns about increased selenium emissions, and additional groundwater contamination stemming from rainwater runoff from the facility’s roof.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

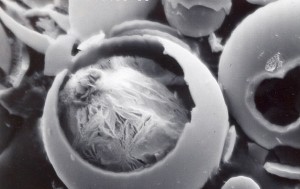

Photo Credit: born 1945, via Flickr.com