Glass tile offers endlessly customizable displays

Decorating – or redecorating – can be both expensive and time-consuming. That’s one reason people don’t often undertake major redecorating projects. Some Italian scientists may have found a way to remove both the inconvenience and expense associated with redecorating. They’ve created Lumentile, a ceramic glass tile that can be used to redecorate a room virtually, and as frequently as the user likes.

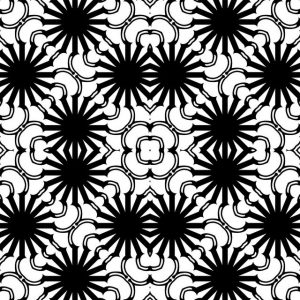

The ceramic tile uses embedded electronics and innovative display technology to display photos, patterns and colors on the surface of the tile. Each tile can be used as an independent segment of a display screen. When the electronics are off, the tile appears to be a standard ceramic tile.

Users can display virtually any image or color on the tile using a computer, smartphone or tablet. A Lumentile wall can be yellow one day and blue the next. In addition, the tiles can display pictures, videos and patterns as the user desires. Each tile is the size of a standard A3 paper – about 11.7″x 16.5″ and contains its own independent power supply.

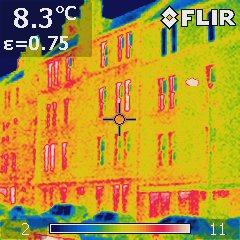

When the tile is unpowered, it can appear in one of three standard colors – black, white or silver. The tile is specially engineered to emit a uniform level of light across the surface of the tile. The designers don’t just envision Lumentile as a decorative surface for interiors. They believe that the tile system can be used for exterior and mobile applications, saying that the system could provide vehicles or other moving objects with a camouflage surface or a mobile billboard.

Lumentile applications aren’t limited to vertical surfaces, either. The designers say that the tiles can be installed on floors to support security and safety applications, or to provide directional assistance. Currently, tiles are in an advanced development phase, and could be on the market by 2020.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. Glassprimer™ glass paint can be used in both interior and exterior applications and can help reduce solar heat gain in some applications. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .