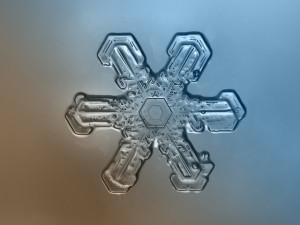

Bio glass might help regrow cartilage

The passage of time and injuries can take their toll on the cartilage in the human skeleton. The body’s capacity to repair itself is well known, but certain tissues don’t self-repair very well or very easily. Cartilage – that flexible, semi-rigid tissue that cushions joints, and gives noses and ears their distinctive shapes – is among those tissues that don’t really regrow. Bio glass developed by scientists at the Imperial College London and the University of Milan Bicocca may change that.

Bio glass could revolutionize joint replacement

The bio glass material acts like cartilage in load-bearing joints in the body, including the knees and spine. It offers the potential to help people who have lost cartilage due to injury or illness, and could help patients avoid having spinal fusion surgery. Spinal fusion is a typical treatment for people who have experienced the degradation or destruction of cartilage between vertebrae. The loss of cartilage causes significant pain, but spinal fusion reduces the patient’s ability to move freely.

The bio glass material, which is a combination of silica and a polymer called polycaprolactone. The compound is exceptionally interesting because it can be made into a biodegradable ink, which could permit 3-D printing of replacement cartilage. The substance can also be used to create a structure that encourages the growth of natural cartilage. It is resilient and shows some ability to “self-heal.”

The ultimate goal for bio glass is to develop a formulation that has the same mechanical properties as natural cartilage, but does not require any additional supportive structure. This would allow the bio glass to be implanted easily in a joint during reconstruction.

Bio glass isn’t new. The initial formulation was developed in then 1960’s as a way to help heal badly damaged bones. The new material is a reformulation of the initial substance, and is designed for both strength and flexibility. Don’t look for the new material just yet, however.

Scientists still need to refine their manufacturing techniques, test the material in humans, and develop ways to implant the material safely. They estimate that the treatment could be perfected and approved for use in about a decade.

While you may have to wait until 2026 for a replacement knee, you can get Glassprimer™ glass paint right now. Glassprimer™ glass paint is an industry leading product formulated especially to bond permanently to glass. Glassprimer™ glass paint can be tinted to match the palette of any major paint manufacturer. If you’d like more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

Photo Credit: Jerry Edmunson, via Flickr.com