Identifying metallic glass failures

Knowing how and where a metallic glass might break gives engineers an advantage when designing parts that need to be ultra-durable – such as parts for a satellite or space vehicle. Metallic glasses typically deform under stress, but they don’t usually break. Their durability is what makes them ideal for extreme environments, so knowing how, why or when a part may break is critical.

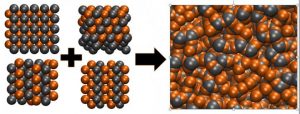

Although the researchers are especially interested in the behavior of metallic glass, their findings could be applied to non-metallic glasses, too. One reason that the glass forms shear bands is that the molecular arrangement of glass (and metallic glass) isn’t crystalline. The amorphous structure of glass allows molecules to continue to move, even when glass has achieved an apparently solid state.

In most cases, when the glass isn’t under stress, molecular movement is imperceptibly slight. When the glass is stressed, however, the molecular movement increases notably. The areas where molecular movement is the greatest coincides with the development of the shear bands in the glass. The shear bands are ultimately the areas of the glass that fail, causing breakage.

The research means that scientists and engineers will be able to more easily calculate the actual strength of glass and metallic glasses quickly. That information can help materials scientists calculate the fitness of a particular glass formulation for a specific application without having to rely on trial-and-error testing.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. Glassprimer™ glass paint can be used in both interior and exterior applications and can help reduce solar heat gain in some applications. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

Photo Credit: Hugh Dutton Associés, via Flickr.com