Flexible glass photovoltaics may lighten soldiers’ load

Research being conducted by the Department of Energy, the Department of Defense and the National Renewable Energy Laboratory (NREL) may lead to the development of lighter weight renewable power sources for soldiers. The goal is to lighten the weight of equipment soldiers typically carry into combat situations, and flexible flass may .

For example, the average Marine carries about 80 pounds of equipment with him or her in combat zones. The equipment includes battery-operated electronic devices. About 25% of the weight in a soldier’s backpack, therefore, is batteries. By developing portable, renewable energy sources, the researchers hope to reduce the weight of combat equipment without sacrificing reliability.

The military makes heavy use of photovoltaic energy now, but current PV power sources are heavy and inflexible. More efficient solar cells have typically been “grown” on heavy glass substrates. Thin-film solar cells are grown on more flexible substrates – stainless steel or titanium – but the thin-film solar cells usually aren’t as beefy as their larger, heavier cousins. To remedy that, the researchers are concentrating on making thin-film solar cells on a heavier substrate, then transferring the thin-film to a lighter weight package.

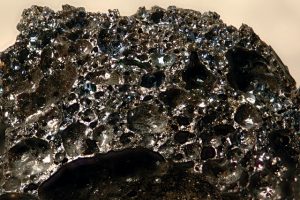

Cadmium-telluride (CdTe) solar cells can be very efficient energy collectors, but they must be created on transparent (glass) substrates. A glass substrate can withstand the high heat required by the manufacturing process. Researchers worked to develop ways to safely detach the high efficiency solar cell from its heavier glass substrate and reattach it to a lighter weight more flexible material. Currently they’re working with liquid nitrogen to detach the thin-film solar cells from glass. (Thin film solar cells are just a few micrometers thick.)

The work is promising and is moving ahead. If successful, thin film solar cells grown on glass substrates could advance the use of unmanned observation and supply vehicles, in addition to helping soldiers on the ground. It’s also likely that the technology would be transferred to commercial use in the future.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

Photo Credit: Voice0Reason, via Flickr.com