Colored electrochromic glass may be available soon

The desire to make glass buildings more energy efficient is strong. By itself, glass isn’t a very good thermal insulator. Heat can pass easily through glass, so whether you’re talking about heat loss or heat gain, the end result for glass isn’t promising.

Scientists have gone out of their way to develop coatings and technologies that can help glass become more energy efficient. Electrochromic glass is one of those technologies that changes the tint on glass from clear to dark, but it also offers the benefit of keeping the inside temperatures manageable.

When the glass switches from transparent to tinted, it rejects the infrared light frequencies that generate extra heat. Currently electrochromic glass comes in one “color” – which happens to be blue. Researchers at the Fraunhofer Institute for Applied Polymer Research IAP in Potsdam-Golm have developed a new technique for creating electrochromic glass in colors other than blue.

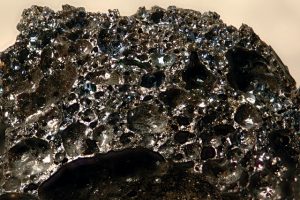

The project is being underwritten by the German government, and could create a range of decorative colored glasses that offer the same or similar energy-saving properties. Currently, electrochromic glass is created by applying a thin film of indium tin oxide or fluorine tin oxide to a single pane of glass. This first coating makes the glass conductive. A second glass pane is similarly prepared, and coated with an additional layer of tungsten oxide, which will change color when voltage is applied. The glass panes are put together face-to-face with a thin electrolyte layer between them.

When a low voltage is applied to electrochromic glass, the tungsten oxide coating darkens enough to reject heat-generating IR lightwaves, but not enough to eliminate visible light transmission. The switch can take some time – between 15 and 20 minutes. That’s true whether the glass is darkening or lightening.

The German researchers are investigating a different production technique that eliminates the second coating of tungsten oxide and using a UV cured resin filling in place of the electrolyte. A direct current to the surface causes form an electrochromic polymer. The technique has a few significant advantages over traditional electrochromic glass. First, a color shift can take place using much less voltage and second, it allows the addition of organic colorants that can produce colors other than blue. Finally, a switch from a transparent state to a colored one can take place in about 30 seconds.

The new manufacturing method also produces glass tiles that are strong enough to be mounted overhead or under foot. It could also be installed in vehicles, like ships or cars.

The new colored electrochromic glass is still in development, but Glassprimer™ glass paint can offer a highly economical substitute for creating colored glass. Glassprimer™ glass paint bonds permanently to glass surfaces and could be used to coat either interior or exterior projects. For more information about Glassprimer™ glass paint, please visit the rest of our website.

Photo Credit: picsessionsart, via Flickr