All glass kitchens gain momentum

Glass is a natural choice for use in the kitchen. It’s tough, easy to clean, impervious to bacteria, and stands up to harsh cleaners. And while its original form is usually transparent, products like Glassprimer™ glass paint make it possible to add a rainbow of color to glass. Some designers have taken glass in the kitchen to a new level by designing all glass kitchens.

What does an all glass kitchen look like

The most recent design showing of an all glass kitchen was at the Venice Architectural Biennale 2016 by Dutch design firm MVRDV. Their rationale for the transparent glass kitchen is simple. According to MVRDV, the all glass kitchen design “…hopes to develop better cuisine by making the processes that go on in our kitchens physically transparent; whether it be food choice, food care, kitchen care, waste choices or the preparation of food itself.”

The Infinity Kitchen was designed by architect Kengo Kuma and media artist Au Yeung Ying Chai, and will be on display until 30th September 2016 in Università IUAV di Venezia Ca’tron. The design is entirely transparent. From cabinets to food preparation surfaces, shelves and cupboards, everything in the kitchen is entirely visible.

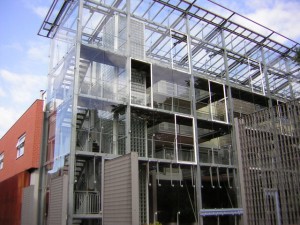

MVRDV has also recently completed an all-glass office in Hong Kong, which was scheduled to open on June 1. The office includes all glass interiors, furniture and equipment.

The idea of an all glass kitchen isn’t new. An Italian design firm – Valcucine – has been working with glass as a primary material for kitchens for about a decade. Their goal, in working with glass, was to design and produce a 100% recyclable kitchen.

Valcucine takes a slightly different approach to working with glass in the kitchen. Rather than working with a completely transparent product, the company’s glass line employs striking colors to bring each glass kitchen to life. In addition to being recyclable, Valcucine took great pains to make their product sustainable and environmentally friendly. The Valcucine glass cabinets are shipped unconstructed, which allows the panels to lay flat for shipping, and reduces the size of the shipping container required to ship each piece.

If you’d like to find more all glass decorating inspiration, please check out the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

Photo Credit: Valcucine