Researcher develops glass antenna

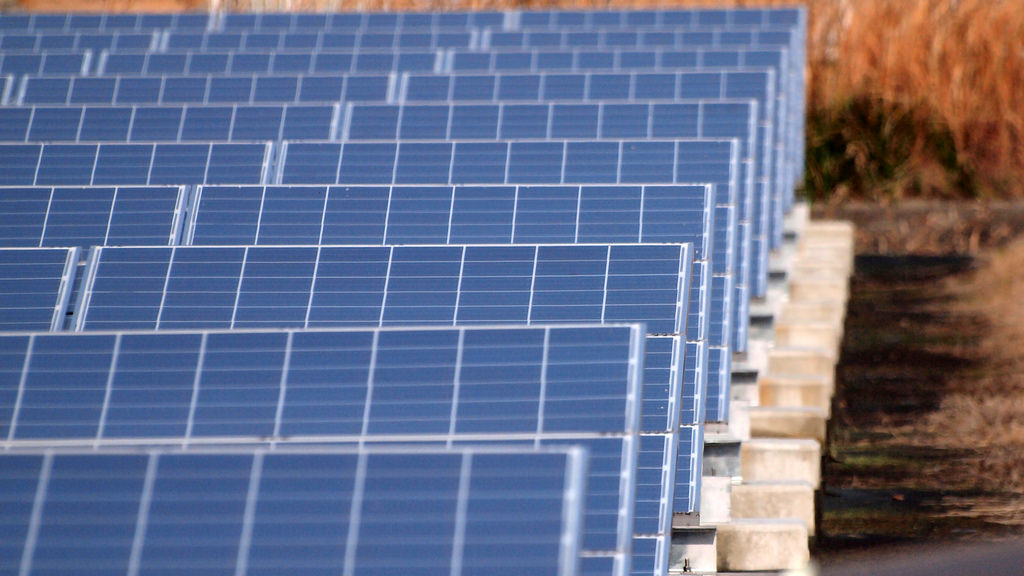

According to Dr. Baktur, an antenna could be printed on solar panels, which would allow sunlight to penetrate the antenna and reach the solar panel easily. That could be important for a space application because it could allow a device to have an antenna that doesn’t interfere with solar energy collection, and that reduces the overall weight of the device at the same time.

In addition, the transparent antenna can transmit data t a higher rate than conventional antennas. The project is still in development, but NASA will be reviewing the work and may apply the technology to an active mission in the future. The research that led to the development of the technology was partly funded by the National Science Foundation and NASA.

The printed antenna could be used in other applications that are closer to home. Baktur says that antennas could be printed on building windows, automobile glass and even clothing. In construction, printed antennas could be used to replace rooftop antennas. In automotive applications, printed antennas could assist in crash detection and other vehicle based telemetry.

The versatility of glass opens opportunities, not just for space-age applications, but also ordinary ones. Glass has been produced for thousands of years, but we’re just now examining the potential of glass.

Glass coatings extend the versatility of glass. For example, Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. It can be tinted to match the paint palette of any major paint manufacturer, and will not chip, fade or peel, even in direct sunlight. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. If you’d like to learn more about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

Photo Credit: Kordite, via Flickr.com