Glass U-values – what are they?

The insulating ability of a material is known as its “R-value.” An R-value describes how quickly a material will lose heat. U-value looks at heat loss differently. Instead of measuring how quickly something will lose heat, the U-value measures how well a material resists losing heat. The R-value and the U-value of a material measure opposite qualities.

The quality of insulation is measured using an R-value. The higher the value, the slower a material will lose heat. The insulating quality of glass is measured with a U-value. In Europe, U-values are also applied to walls. Knowing how well something insulates, or how quickly it will lose heat helps people to understand the energy costs associated with a material.

U-values describe heat transfer – whether heat is moving into or out of a building. The lower the U-value, the better the material will resist heat transfer. For controlling energy consumption, it’s important to control heat transfer. With regard to windows, all components of the window have a U-value. That means window glass has a U-value, but so does the window frame. The glazing on the glass has its own U-value. Materials with very different U-values that are used to make a unit like a window can reduce the unit’s overall ability to stop the transfer of heat. The more similar the U-value of a unit’s components, the more similar the U-value of the finished product will be. Glass has a low R-value, so by definition, it has a high U-value.

The “leakiest” part of a window is actually the window frame. Small windows end up with a high U-value (which is bad), because the frame – which is the weakest link – comprises a larger proportion of the window unit than the frame of a large window. That’s important to keep in mind. Glass isn’t a great insulator, but the window frame and the glazing actually have a bigger impact on the window’s energy efficiency.

Glass coatings can change the performance of glass. Glassprimer™ glass paint is one good example. Glassprimer™ glass paint is highly UV-resistant, which means that it can block the transmission of UV light waves, which tend to cause colors to fade, and can help reduce solar heat gain by reducing the overall transmission of the full spectrum of light.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

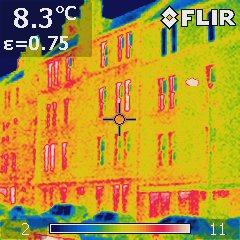

Photo Credit: Greener Leith , via Flickr.com