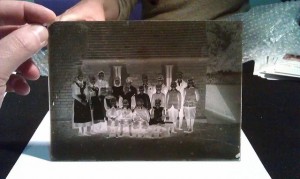

Iconic Glass Structures – R&F Yingkai Square

This week, we look at R&F Yingkai Square a newly constructed glass and steel tower in the Guangzhou Province in Zujiang. Its shifty shape is a visual treat because it’s a departure from the standard “four square” building. The tower is a mixed-use environment, and it’s nearly full.

The tower’s design is inspired by bamboo plants. It features asymmetrical “corners” that, when combined with the steel strips on the outside faces, make the building appear to move. The steel facing at the base gives way to glass at top of the building. The change in texture and the building’s faceted corners draw the eye ever upward, also lending to the notion of a building in motion.

The building tenants include the Park Hyatt Guangzhou on the upper floors, and a host of offices on the lower floors. The building also includes residential spaces. The tower extends 66 floors (nearly 1,000 feet) up and five floors below grade, and overlooks the Pearl River. Hotel guests can take advantage of spectacular views from the hotel’s infinity pool, and enjoy a meal in the hotel’s rooftop eatery and garden.

R&F Yingkai Square is currently the 9th tallest building in Guangzhou and the 49th tallest structure in China. It’s brand new construction, having been designed by Goettsch Partners of Chicago in 2008. Construction on the building was completed in 2014 and the building was formally opened earlier this year.

The building is owned by Guangzhou R&F Properties Co., Ltd., which also provided structural engineering services and was the primary contractor for the building’s construction.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store.

Photo Credit: 1st image via CTBUH