Upgraded sorting machines might save glass recycling

A growing concern among municipalities, materials recyclers and individual consumers is the possibility that glass recycling will come to a halt. Environmentally, there is no debate about the value of recycling glass. Glass is virtually infinitely recyclable, and consumes less energy during recycling than making new glass does.

Glass manufacturers would like to add more cullet (ground glass that’s ready for recycling) to their materials mixture, but the logistics of glass recycling make that difficult. Glass is heavy, and before it’s ground into cullet, it’s bulky. More importantly, glass needs to be sorted precisely. Different glass formulations can’t be mixed together. Significantly, heat-treated glass (tempered glass and Pyrex), colored and leaded glass need to be separated from the rest of the glass recycling stream, as these formulations cannot be used for containers.

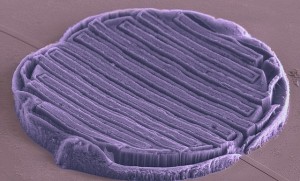

X ray fluorescence and glass sorting

The emergence of X-ray fluorescence glass sorting machines may help take the sting out of glass recycling. Although the system was originally developed for glass recycling, manufacturers can also use the same technology to sort other types of recyclables. For example, Redwave’s latest sorter can identify and sort mixed heavy metals, including copper, zinc and stainless steel. It can also sort brominated plastics and a range of glass formulations.

Being able to sort recycling quickly is one key to reducing the cost associated with it. It’s also one way to ensure that glass recycling can be conducted as efficiently as possible. The challenges of recycling are real – especially for glass. A number of municipalities have already dropped or scaled back their glass recycling programs. In other cases, glass is still collected at the curb, but it is pulverized and used not as cullet, but as daily cover for landfills. One rationale for doing that is that the pulverized glass is heavy enough to hold down potential “fly-away” materials. Glass is also inert, so it poses no long-term danger from leeching or disintegration.

Municipalities are still working on ways to preserve their glass recycling programs, in part because consumers understand the recyclability of glass, perhaps better than any other material. Improved sorting technology may be able to enhance the efficiency of the glass sorting process.

Glassprimer™ glass paint is a specialized glass coating that bonds permanently to glass surfaces. GlassPrimer also makes a glass surface molecular activator that is designed to work with UV-inkjet glass printing processes. For more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store.

Photo Credit: Rockman of Zymurgy, via Flickr.com