MIT Researchers Develop Switchable Glass

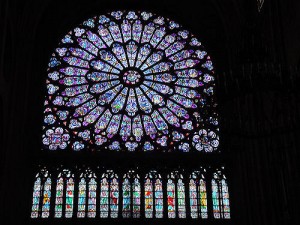

Switchable glass – glass that changes from transparent to opaque and back again – isn’t new, but researchers at MIT have developed a glass that uses power only when the glass switches. The stable-state switchable glass could significantly reduce energy consumption in buildings that receive direct sunlight, and also offer a low-power alternative to traditional switchable glass.

Switchable glass doesn’t require power

Typically, switchable glass requires power to remain in its opaque state. The regular (although low) power drain diminishes the savings that the glass generates. By developing glass that requires power only when it is actively switching states, the team has created a potentially new option for energy-saving glass.

The new glass is made from electrochromic materials, rather than photochromic ones. The new material switches states instantly when electricity is applied. In contrast, photochromic materials have a delayed response to the presence of light. Existing electrochromic materials also have similar limitations, and require constant power to retain their opacity.

Electrochromic materials rely on the movement of both electrons and positive ions to create an opaque effect. While electrons move very quickly, positively charged ions – which do the actual color-changing work, do not. When the electrical current is discontinued, the negative electrical state that attracts the positive ions is canceled, which also cancels the opacity of the glass.

The new glass uses metal-organic frameworks (MOF), which can conduct both electrons and positive ions very quickly. This eliminates the delay in achieving opacity. Another benefit of the technique is that the research team has been able to create a “near-black” color when the glass is opaque.

The glass also uses a combination of an organic material and a metal salt that self-assembles into a thin film that can switch between virtual transparency and virtual opacity quickly.

The glass is still experimental, and the researchers are currently working with very small glass. The next step is to increase the size of the glass and verify that the properties it displays on a small scale still work on a larger scale. If perfected, the glass could be used in buildings, airplanes and other locations where it can address issues of glare or energy consumption.

One way to address both glare and energy consumption today is through the use of Glassprimer™ glass paint. Glassprimer™ glass paint provides exceptional UV-light rejection while allowing visible light transmission. Glassprimer™ glass paint is applied directly to glass, and makes a permanent bond with the glass. It is suitable for both interior and exterior use, is available in virtually any color and costs about $1 per square foot.

If you’d like more information about Glassprimer™ glass paint, please visit the rest of our site. If you’d like to purchase Glassprimer™ glass paint, please visit our online store .

Photo Credit: Khalid Abdulaziz Kaabi and Dennis Sheberla